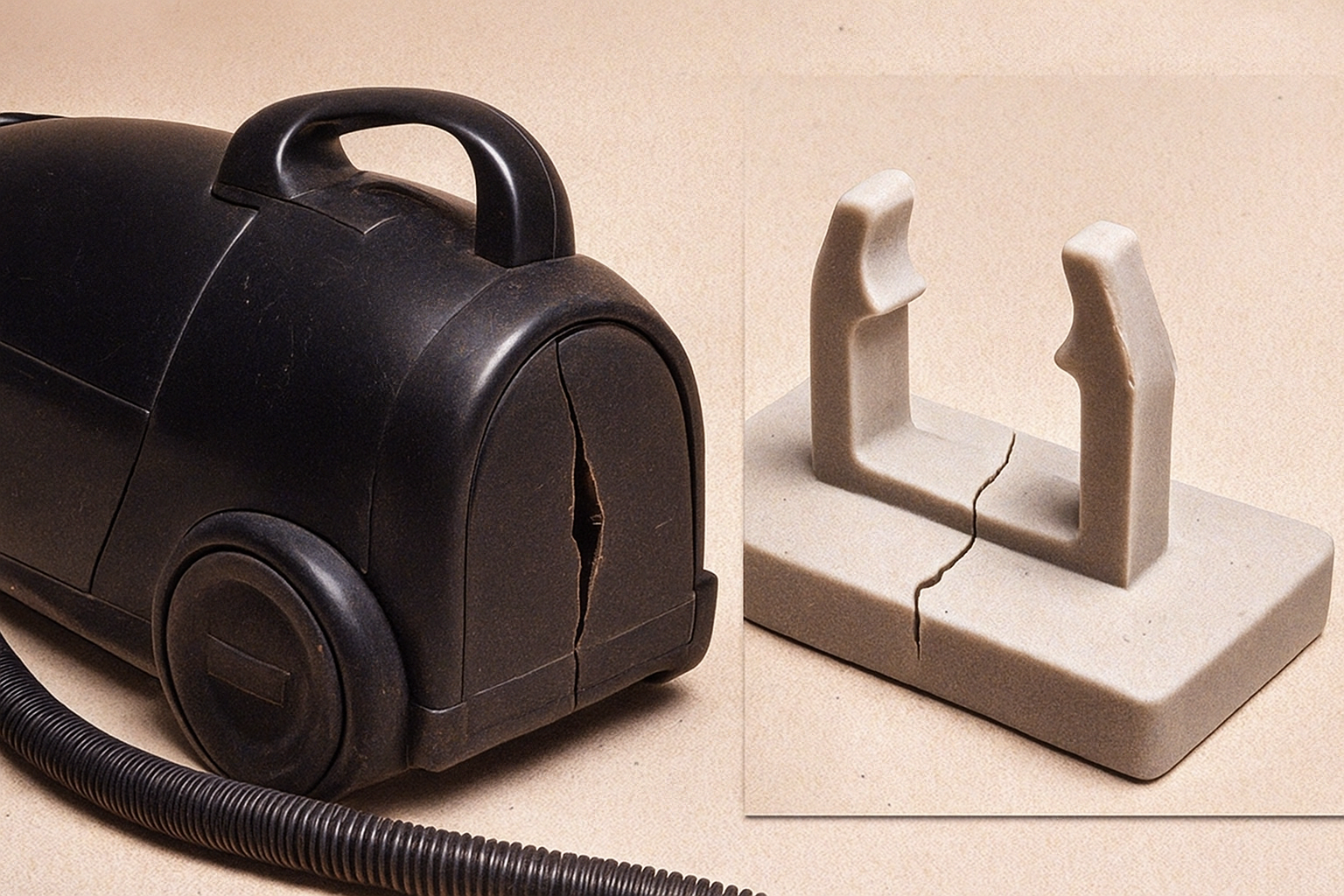

“The click that feels satisfying on day one can become the crack you hear in year three.”

Snap-fit connections make vacuum assembly fast and elegant—no screws, no glue, easy replacement.

But every flex leaves a microscopic scar. After thousands of open-and-close cycles, temperature changes, and stress concentration, those little scars turn into fractures.

Understanding why this happens is essential for anyone designing or sourcing Multi-Functional Durable Vacuum Cleaners or Cordless Vacuum Cleaners that must survive years of use.

🧩 1. Why Designers Love Snap-Fits

Snap-fits reduce manufacturing cost, weight, and assembly time.

A single molded hook or cantilever replaces multiple screws, keeping housings slim and modular—ideal for Energy-Saving Efficient Powerful Vacuum Cleaners and compact Portable Quiet Vacuum Cleaners.

They also simplify maintenance: service teams can replace filters or batteries quickly without special tools.

The trade-off? Every time a latch bends, plastic fibers stretch beyond their elastic limit. Fatigue begins invisibly.

🔬 2. How Cracks Begin

🔩 a. Stress Concentration

Sharp internal corners at the root of the latch act as magnifiers for strain.

Under repeated loading, molecular bonds separate, forming a crack that grows with each flex.

🌡️ b. Creep and Temperature

Inside Wet Dry Vacuum Cleaners, motor heat keeps plastic warm for hours.

Warm polymers deform slowly (creep). When cooled, they shrink unevenly, adding tension.

💧 c. Chemical Attack

Detergent residue, UV light, or ozone exposure weakens surface chains.

Once the surface loses flexibility, the next snap-fit cycle finishes the fracture.

⚙️ d. Assembly Force Variation

If the factory’s automation presses parts at inconsistent angles or speeds, tiny misalignments create permanent pre-stress. Months later, the latch snaps “by itself.”

🧱 3. Material Matters

| Material | Pros | Cons |

|---|---|---|

| ABS | Rigid, low cost | Brittle after aging |

| POM (Acetal) | Excellent fatigue strength | Sensitive to moisture |

| PA66 + GF | High stiffness, heat resistance | Needs precise mold temp |

| PC/ABS blend | Balanced toughness | Costly |

For repeated access components—dust bins, filter doors—PC/ABS or nylon with 15–30 % glass fiber resists fatigue far longer than plain ABS.

Soft-touch TPE overlays can also absorb impact energy, protecting the hinge root.

🧠 4. Designing for Fatigue Life

Add generous fillets (≥ 0.5 × wall thickness) at every corner.

Control deflection angle—no more than 0.8 × elastic limit of the material.

Provide insertion ramps so hooks glide, not snap abruptly.

Use multiple small latches instead of one large one; load sharing delays failure.

Simulate cycles with finite-element analysis (FEA).

A well-engineered snap-fit on a Large-Capacity Wet Dry Vacuum Cleaner can endure 5 000 cycles before visible whitening; a poor one breaks in 50.

🧪 5. Testing and Quality Verification

OEMs involved in vacuum cleaner distribution and vacuums procurement should insist on:

Cycle-fatigue test: 5 000 open/close cycles at 25 °C and 60 °C.

Pull-off force test: latch must hold ≥ 150 % of assembly load.

Aging test: 48 h at 70 °C plus UV exposure; inspect for micro-cracks.

Fit-and-release consistency: force variation < 10 %.

Reliable suppliers document these metrics just as carefully as suction power.

🧰 6. Maintenance and User Impact

Most users never see the latch until it breaks.

Designing service instructions that remind customers to press release buttons instead of pulling panels prevents accidental overstress.

For professional units, providing spare latches or modular shells ensures fast repair without full housing replacement—an approach now common in 4 in 1 Cordless Smart Wet & Dry Vacuum Cleaners.

🌍 7. Sustainability and Modularity

Durable snap-fits also support sustainability.

A modular body that opens cleanly can be recycled or serviced instead of discarded.

Modern Energy-Saving Efficient Powerful Vacuum Cleaners use replaceable latch modules made from recyclable polyamide—strong, repairable, and eco-friendly.

Fewer screws mean faster disassembly at end-of-life, aligning with circular-economy goals.

✨ Conclusion

Every satisfying “click” hides a world of mechanical stress.

Over-stressed snap-fits transform elegant assembly into predictable failure.

By combining fatigue-resistant materials, generous geometry, and verified testing, designers ensure the next click remains silent—not because it broke, but because it worked perfectly.

“Good design doesn’t fight plastic—it respects its limits.”

Long-lasting connection systems define the reliability of the entire vacuum, from battery door to dust bin hinge. Strong joints build strong reputations.

🔗 Explore More

For deeper resources on mechanical design, fatigue simulation, and product reliability, visit

👉 www.lxvacuum.com — the global knowledge hub for vacuum engineering and sustainable product innovation.

📊 SEO TAG

snap-fit design, vacuum housing latch, plastic fatigue, multi-functional durable vacuum cleaner, cordless vacuum cleaner, wet dry vacuum cleaners, portable quiet vacuum cleaner, energy-saving efficient powerful vacuum cleaner, large-capacity wet dry vacuum cleaner, vacuums procurement, vacuum cleaner distribution, mechanical fatigue testing, plastic hinge design, polymer stress analysis, snap joint engineering, material selection, PC ABS blend, nylon glass fiber, assembly design, injection molding optimization, durability testing, component replacement, recyclable design, sustainable vacuum, structural reliability, fatigue simulation, vacuum repair, service design, housing modularity, product maintenance, long life vacuum, design optimization, product engineering, mechanical testing, assembly integrity, manufacturing quality, recyclable materials, eco design, snap fit cycle test, plastic creep, aging resistance, vacuum product development, end user maintenance, sustainable engineering, innovation in appliances, mechanical stress, durability engineering, vacuum component testing, design verification, product lifecycle, engineering guide, vacuum technology.